Designed for the latest high precision mold base and components.

The bed adopts an unique "M" type rib structure, even stress and stable bearing.

Integrated structure for column and crossbeam, circular cavities and reasonable reinforcing ribs are set in the box-type cavity, which has high torsional and bending rigidity.

Equipped with 15 inch large screen color display and calculator as standard to improve the operator's operation experience.

Select Japanese brand lubrication and pneumatic system to ensure high reliability, which is installed centrally in front of the machine, it's convenient for the operator to observe and maintain.

Designed with symmetrical and movable door in front to provide large loading and unloading space, which is safe and convenient.

Equipped with two coil chip conveyors and a chain chip conveyor, cutting chips can be discharged efficiently to the back side of the machine in a centralized way.

|

Items

|

Unit

|

VM2000

|

|

Standard controller

|

|

FANUC 0i—MF plus absolute type 0 15"LCD

|

|

Travel

|

X axis travel (saddle)

|

mm

|

2000

|

|

Y axis travel (work-table)

|

mm

|

1300

|

|

Z axis travel (spindle head)

|

mm

|

800

|

|

Work table

|

Table size (length×width)

|

mm

|

1650x1300

|

|

Spindle

|

Spindle taper

|

|

BBT50

|

|

Max. spindle speed

|

rpm

|

6000(Direct driven)

|

|

Spindle motor power(continual working/Max.)

|

kW

|

22/54

|

|

Spindle torque(continual working/Max.)

|

N.m

|

770/1892

|

|

Accuracy

|

VDI/DGQ3441

|

Full travel positioning accuracy

|

mm

|

P0.015

|

|

Repeatability accuracy

|

mm

|

Ps0.012

|

|

Machine size (length/width/height)

|

mm

|

5000x4910x4600

|

|

Machine weight

|

kg

|

19500

|

We reserve the right to change technical parameters for improvement of our products without giving notice to customers.

|

|

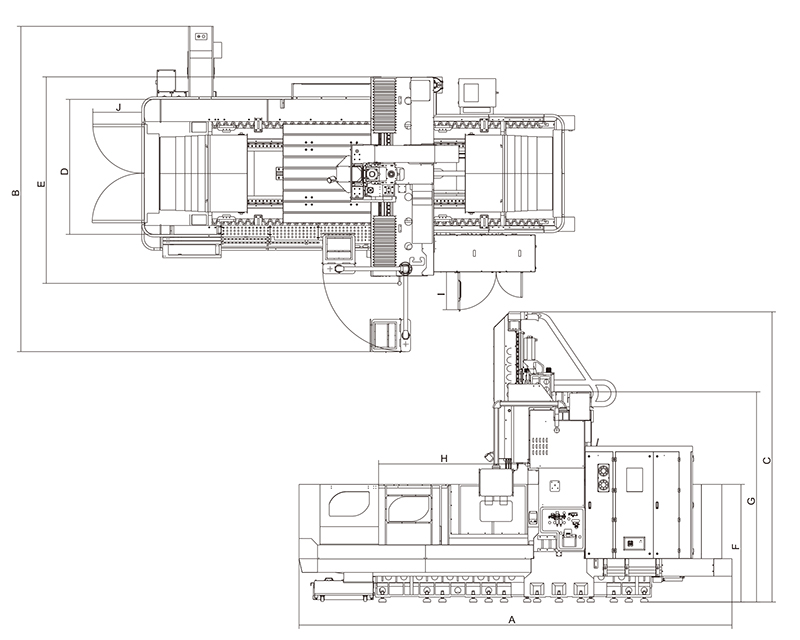

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

I

|

J

|

|

VM2000

|

5000

|

4910

|

4600

|

3270

|

3270

|

2630

|

3213

|

1690

|

740

|

0

|

We reserve the right to change technical parameters for improvement of our products without giving notice to customers.